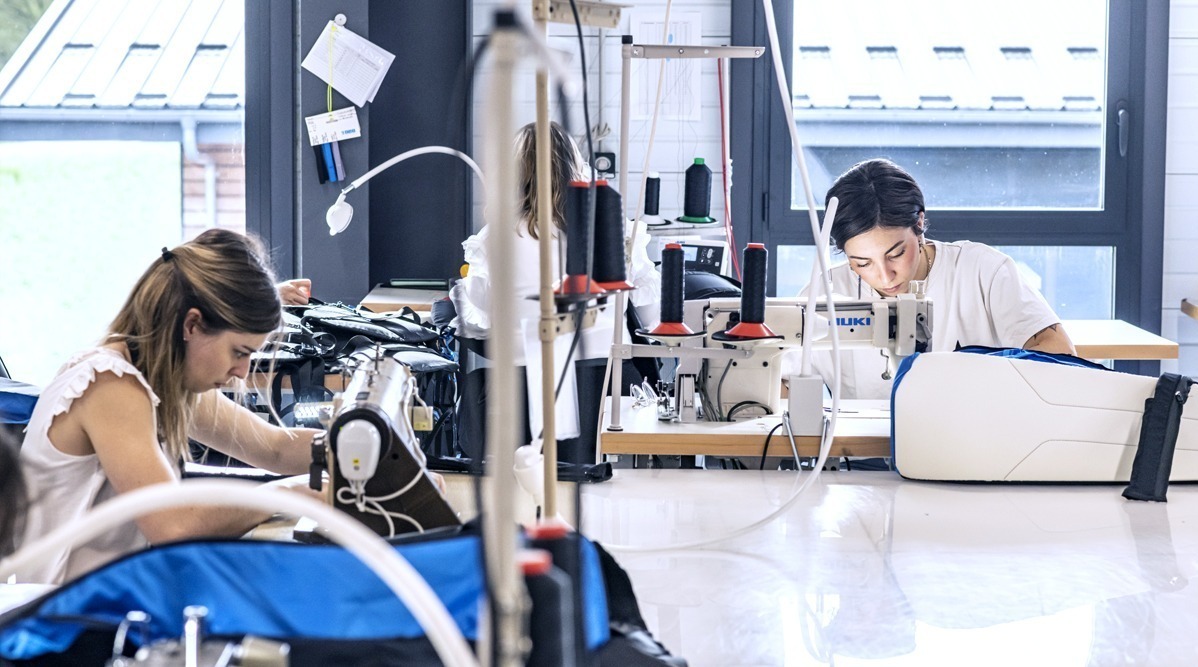

Since 2013, NEO has been designing and manufacturing high-end textile products for paragliding and outdoor activities in its unique workshop located on the shores of Lake Annecy in Haute-Savoie. We believe in local, responsible production methods that promote the excellence of French couture and preserve rare skills in our region.

Controlling the entire production chain, from cutting the fabric to shipping, allows us to innovate more effectively and be extremely flexible in the design of our products. This expertise is at the heart of our commitment: to offer innovative and sustainable equipment that guarantees our users comfort, safety, and freedom of movement.

We are proud to have been the only brand manufacturing paragliding harnesses, as well as speedriding wings and harnesses, in France for over 10 years.

At NEO, we believe that the excellence of our products is based above all on this exceptional expertise.

We are proud to manufacture here. nowhere else.

« It’s a bold gamble we’ve taken, going against the grain of everything else that’s being done. »

Eric Roussel, founder and CEO of NEO.

NEO harnesses, sails and travel accessories are entirely made in France in our workshop in Haute-Savoie. This choice of local production allows us to offer high quality products.

Our original and innovative products are conceived and designed by our team in Haute-Savoie, on the shores of Lake Annecy. Our R&D team and our ambassadors test our products intensively before the final production run.

Our innovative products with high added value allow us to finance a French workforce. We are proud to take part in the effort of relocating the know-how of the textile subsidiary from Asian countries to France.

At NEO, we give ourselves the means to do what we love. Passion is our driving force.

First and foremost, NEO is the story of a paragliding and speedriding enthusiast who has never ceased to refine their practice through an approach of permanent innovation.

Then, it’s our passion for excellence in French manufacturing that drives us every day to create the best possible products.

The NEO brand is represented by ⵣ (yaZ), the symbol for “Free Man” in the Berber language.

It is first, the passion for free flying. It is also the freedom of a fluid and light movement, that we prioritise during the conception of our products.

Finally, it is the freedom to get off the beaten track, which gives us the means to live our passions without hindrance. It is this principle that has guided our choice of local production without conforming to the matrix of global supply chains.

This choice is fully adopted in order to maintain total freedom in our design and manufacturing processes.

NEO stands for common sense. We design products that are durable, robust and timeless. We are proud to contribute, in our own way, to a more conscious and responsible consumption.

The quality of our know-how guarantees the robustness of our products for long-term use. In the framework of sustainability, we offer all our customers a “guarantee and repair” service, provided by the workshop. It is common sense to ensure that our customers can get their products repaired for life, rather than having to throw them away when a single part is worn out.

It is also to offer to drop them off in person directly to our workshop for immediate repair whenever possible, instead of sending them by post and thus adding to the carbon footprint.